Furnace & Solutions

Precision temperature control, high energy efficiency, and industrial-grade reliability.

We provide custom furnace solutions based on your unique melting needs, output requirements, and factory layout.

High-performance melting, holding, and transportation systems engineered for continuous and stable operations.

Talk to our engineering team to explore the most efficient and cost-effective solution for your application.

What We Do

Industrial Furnaces & Custom Solutions for Aluminum and Zinc Alloys

High-efficiency central melting furnaces designed for continuous aluminum/zinc alloy processing.

Energy-saving electric and gas holding furnaces to maintain temperature and reduce metal loss.

Compact and flexible furnaces ideal for smaller batch operations and alloy testing.

Safe and efficient aluminum liquid transportation through pipelines with optional heating.

From layout planning to furnace integration, we support complete project implementation.

Environmentally compliant waste gas and dust treatment for clean and safe operations.

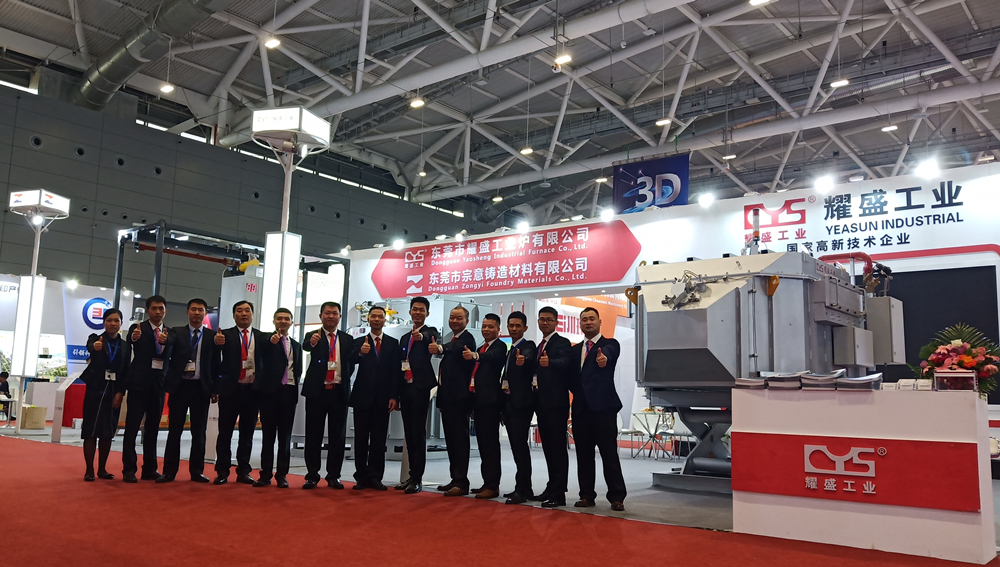

Who we are

A Leading Industrial Furnace Manufacturer Since 1978

Founded in 2008, Dongguan Yeasun Industrial Furnace Co., Ltd. builds on the legacy of Yeasun Taiwan, established in 1978. With over 40 years of expertise, Yeasun specializes in designing and manufacturing industrial furnaces for aluminum and zinc alloy melting and holding.

Industrial Furnaces Delivered

To foundries, die-casting plants, and metal processors worldwide.

Why Choose us

Real Engineering. Real Performance. Real Results.

Every furnace is tailored to your voltage, layout, and production goals.

Designed to meet your target capacity—efficient, stable, and scalable.

Advanced design principles with locally supported manufacturing.

Fume treatment and energy-saving solutions to meet environmental standards.

Trusted partner for OEM/ODM clients with full confidentiality assurance.

Pre-sale consultation and 24/7 post-sale service.

Backed by 50+ invention patents and collaborations with leading universities, we continuously deliver cutting-edge, high-performance systems.

From furnace design to whole plant layout and environmental systems — we help you save cost, avoid safety risks, and ensure process integration.

From melting, holding, and crucible furnaces to fume treatment and aluminum transport systems — we cover all your aluminum and zinc alloy processing needs.

Join 3,000+ Industrial Clients Who Trust Yeasun

We don’t just build furnaces — we build long-term partnerships.

Join a global community of manufacturers who rely on Yeasun for energy-efficient, custom-engineered thermal systems.

📌 Exported to over 36 countries, including Germany, India, Turkey, and Vietnam.

📌 Serving industries from automotive components to aluminium hardware.

From concept to commissioning — we turn your smelting goals into reality.

How it works

From Idea to Installation — A Seamless Process

🔍 Technical Consultation

Understand your needs and propose the right solution.

📝 Customized Proposal & Quotation

Tailored offer based on your specs and budget.

🏭 Manufacturing & Inspection

Strict quality control during every production stage.

🚚 Delivery & On-Site Support

Timely shipping and installation guidance if required.

Trusted by 25,000+ world-class brands and organizations of all sizes.

What is the power supply of the industrial furnace?

The customer determines the power supply. We can either match your local voltage and phase directly or adjust it using a transformer, ensuring the furnace is ready to use upon installation at the end user’s site.

What information should the customer provide for an accurate quotation?

To provide an accurate and efficient quotation, please share the following:

Technical requirements/specifications

Drawings or reference pictures

Industrial voltage (local power supply details)

Planned daily or hourly output/capacity

Any special requests (e.g., size limits, automation level, etc.)

What are the payment terms?

40% down payment by T/T

60% balance payment before delivery

What is the delivery time?

The delivery lead time is 15–30 working days after receipt of the down payment, depending on the order quantity and customisation level.

Let's work together

Ready to improve quality, lower cost, or scale up production? Talk to our engineering team—trusted for over four decades.