Aluminum die casting requires not only precise tooling and process control, but also stable melt quality. Among various non-metallic inclusions, MgO (magnesium oxide) inclusions are one of the most common and most underestimated problems in aluminum die casting production.

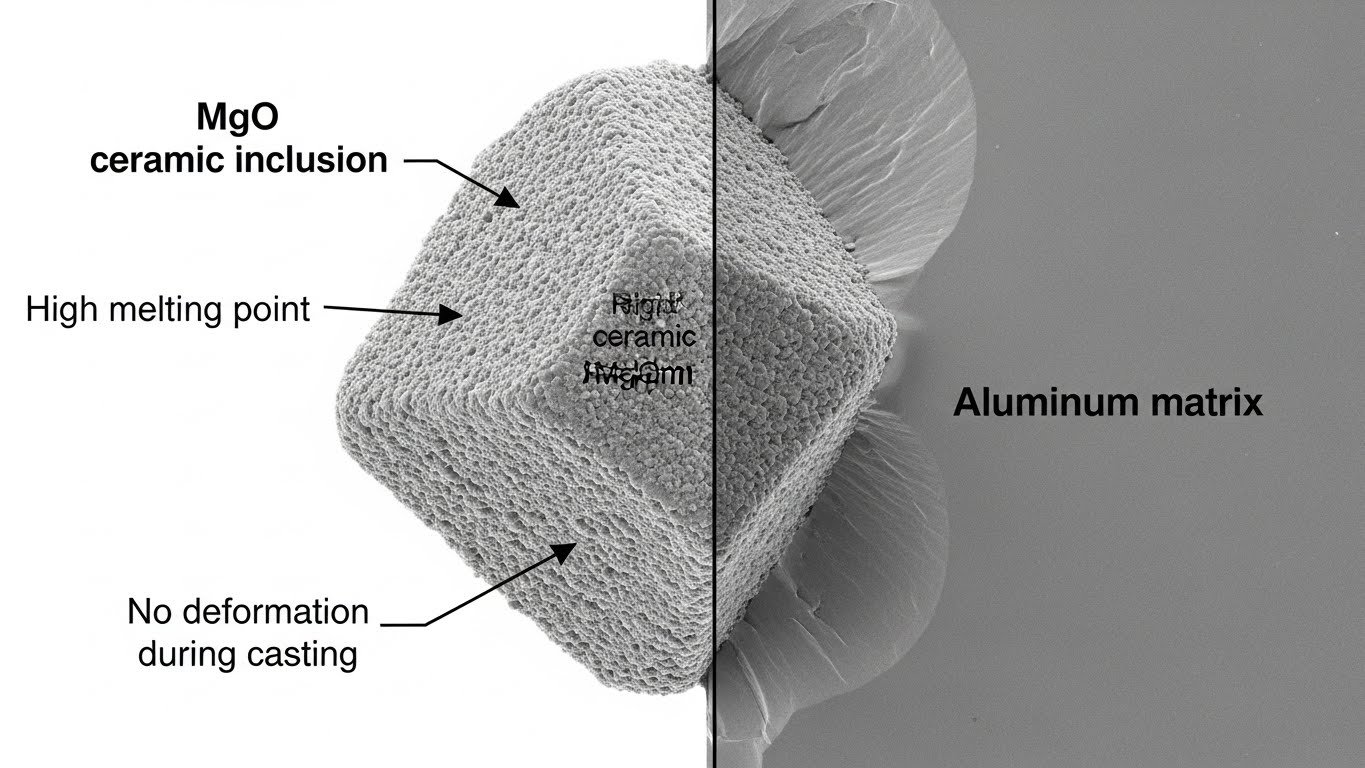

Unlike gas porosity or shrinkage defects, MgO inclusions are solid, rigid ceramic particles that cannot be removed by remelting alone. Once they enter the die cavity, they become embedded defects that directly affect mechanical properties, surface quality, and process stability.

This article provides a practical, engineering-oriented overview of MgO inclusions in aluminum die casting — focusing on where they come from, how they cause defects, and how they can be effectively controlled in industrial production.

Why MgO Inclusions Are a Critical Issue in Die Casting

In high-pressure die casting, aluminum melt experiences:

- High temperatures

- Long holding times

- Frequent melt transfer

- Strong turbulence

These conditions significantly increase the risk of oxidation, especially for Mg-containing aluminum alloys such as AlSiMg, A380, ADC12, and other modified die casting alloys.

MgO inclusions are particularly harmful because they are:

- Hard and non-deformable

- Chemically stable

- Difficult to float out naturally

- Easy to misidentify as other defects

As a result, MgO inclusions often lead to unstable quality, where defects appear intermittently and are difficult to trace back to a single process parameter.

This correlation between melt cleanliness, inclusion content, and defect formation has been widely observed in industrial die casting practice and experimental studies on melt cleanliness and inclusion control in die casting.

What Are MgO Inclusions in Aluminum Melts?

MgO inclusions are solid magnesium oxide particles formed during aluminum melting and melt treatment processes.

From an engineering perspective, their key characteristics are:

- Very high melting point (~2850°C)

→ They remain solid throughout melting, holding, and casting. - High hardness (ceramic-like behavior)

→ They act as rigid stress concentrators inside the aluminum matrix. - Poor wettability with aluminum

→ Weak bonding at the inclusion–matrix interface.

Once entrapped in the melt, MgO particles travel with the aluminum into the die cavity and become permanent defects in the casting.

Typical Die Casting Defects Caused by MgO Inclusions

MgO inclusions rarely cause only one type of defect. Instead, they reduce the overall robustness of the die casting process.

Common problems include:

Surface Defects

- Black spots or dark streaks

- Rough surfaces after machining

- Poor cosmetic appearance in visible parts

Cracks and Reduced Mechanical Properties

- Lower elongation

- Early crack initiation

- Reduced fatigue life

Machining and Tool Wear Issues

- Hard MgO particles accelerate cutting tool wear

- Poor surface finish during CNC machining

Poor Anodizing or Coating Quality

- Non-uniform oxide layers

- Color variation and coating defects

From a quality engineering standpoint, MgO inclusions often explain why mechanical properties or surface quality fluctuate even when process parameters appear unchanged.

Main Sources of MgO in Aluminum Die Casting Melts

1. Magnesium Oxidation During Melting and Holding

Magnesium is highly reactive at elevated temperatures. During melting and holding:

- Mg reacts rapidly with oxygen

- Oxide films form on the melt surface

- These films can break and be entrained into the melt

Long holding times, high melt temperatures, and poor furnace sealing significantly increase this risk.

2. Flux-Related MgO Formation

Fluxes containing magnesium chlorides are commonly used for cleaning and degassing aluminum melts. However:

- Moist or improperly stored flux can decompose

- Excessive flux usage increases oxide generation

- Localized reactions may produce fine MgO particles

Flux-related MgO particles are often small and well-dispersed, making them especially difficult to remove.

3. Melt Turbulence and Re-oxidation

Turbulence is one of the biggest enemies of melt cleanliness:

- Aggressive stirring

- Unprotected melt transfer

- Splashing during pouring

These actions continuously expose fresh melt surfaces to air, accelerating Mg oxidation and generating new MgO inclusions even after degassing.

Practical Methods to Control MgO Inclusions in Die Casting

MgO inclusions cannot be completely eliminated, but they can be controlled to a stable and acceptable level through disciplined process management.

Quantitative studies on melt purification techniques for non-metallic inclusion removal show that coordinated refining, degassing, and filtration steps significantly reduce inclusion content and improve melt quality.

Key Control Measures

- Use low-moisture, properly dried fluxes

- Avoid excessive flux addition

- Control melt temperature and minimize holding time

- Apply inert gas (argon or nitrogen) protection

- Use fine-bubble degassing without excessive turbulence

- Install ceramic foam filters with appropriate pore size

- Reduce turbulence during melt transfer and pouring

From an industrial perspective, effective fluxing, degassing, flotation, and filtration remain the most practical tools for inclusion control.

Industry-oriented summaries of fluxing and degassing methods for inclusion removal highlight how these techniques are applied in real foundry environments.

Conclusion: MgO Control Is a Process Discipline Issue

MgO inclusions are an unavoidable reality in aluminum die casting, especially for magnesium-containing alloys. Their impact depends entirely on how well the melting and melt treatment process is controlled.

Stable die casting quality is achieved through:

- Controlled melting conditions

- Disciplined melt handling

- Effective filtration and degassing

- Consistent process execution

In practice, stable melt quality is the foundation of stable die casting quality — and controlling MgO inclusions is a key part of that foundation.