Holding Furnace

High-Performance Aluminum Holding Furnace Solutions

An Aluminum Holding Furnace is essential for maintaining molten aluminum at the right temperature between melting and casting stages. Our advanced holding solutions are engineered to ensure stable temperature control, minimal oxidation, and superior energy efficiency.

We offer two main types to suit different production needs:

- Gas-Fired Continuous Melting Holding Furnace (Machine-Side) – Designed for small to medium-scale die-casting operations, combining melting, holding, and ladling functions in one unit.

- Coreless Electric Holding Furnace – Designed for high-precision aluminum holding with no crucible, achieving exceptional energy efficiency and temperature stability.

Need more options?

Didn’t find the exact holding furnace you’re looking for?

We can design and build a custom gas-fired or electric model tailored to your capacity, fuel type, and plant layout.

Contact our team today to discuss your requirements and get a solution that fits perfectly.

Solving the Key Challenges in Aluminum Holding

Industry Challenges

Fluctuating Molten Metal Temperature

High Oxidation and Metal Loss

Excessive Fuel or Energy Consumption

Inefficient Manual Feeding

Limited Space Near Casting Machines

Our Solutions

Maintain ±5°C Stability

Precision temperature control systems ensure molten aluminum remains within ±5°C, improving casting consistency and reducing defects.

Reduce Burn-Off to ≤1.1%

Excessive Fuel or Energy Consumption

High-grade refractory and insulation materials reduce heat loss, cutting fuel or electricity use while maintaining efficiency.

Automated Charging System

Compact, Customizable Design

Why Choose us

Real Engineering. Real Performance. Real Results.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Every furnace is tailored to your voltage, layout, and production goals.

Designed to meet your target capacity—efficient, stable, and scalable.

Advanced design principles with locally supported manufacturing.

Fume treatment and energy-saving solutions to meet environmental standards.

Trusted partner for OEM/ODM clients with full confidentiality assurance.

Pre-sale consultation and 24/7 post-sale service.

Backed by 150+ invention patents and collaborations with leading universities, we continuously deliver cutting-edge, high-performance systems.

From furnace design to whole plant layout and environmental systems — we help you save cost, avoid safety risks, and ensure process integration.

From melting, holding, and crucible furnaces to fume treatment and aluminum transport systems — we cover all your aluminum and zinc alloy processing needs.

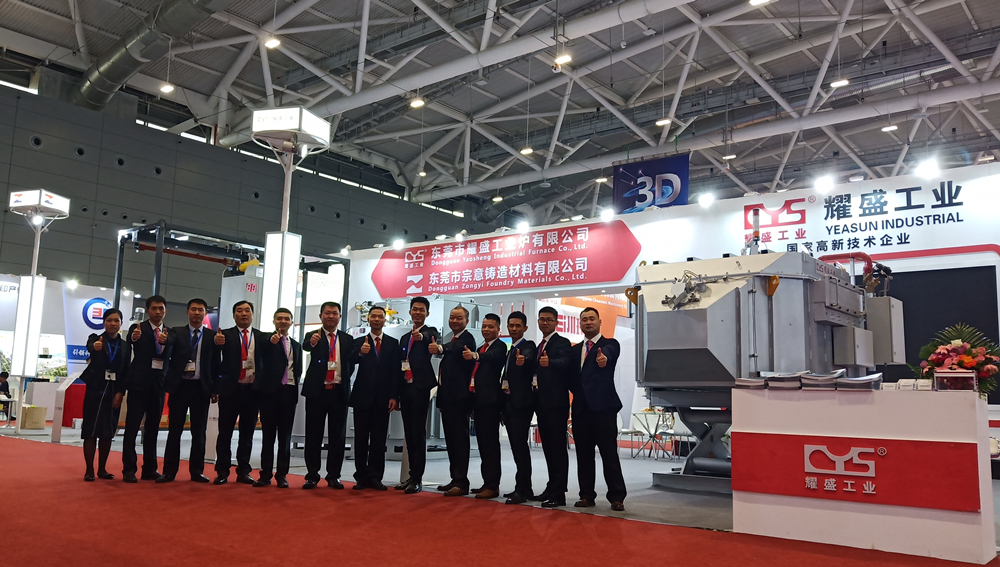

Join 3,000+ Industrial Clients Who Trust Yeasun

We don’t just build furnaces — we build long-term partnerships.

Join a global community of manufacturers who rely on Yeasun for energy-efficient, custom-engineered thermal systems.

Common Questions

Most Popular Questions.

Find answers to the most common questions about our gas-fired and electric holding furnaces — covering capacity, temperature control, fuel options, maintenance, and customization to fit your production needs.

Gas-fired models are ideal for facilities that require melting and holding in one unit; electric models are best for precise holding with minimal oxidation.

≤1.1% for gas-fired models, even lower for electric models.

Gas-fired models: 100–500 kg/h; electric models can be tailored for specific capacity needs.

Yes, both designs are built for continuous operation with proper maintenance.

Yes, our engineers provide full on-site installation, commissioning, and operator training worldwide.