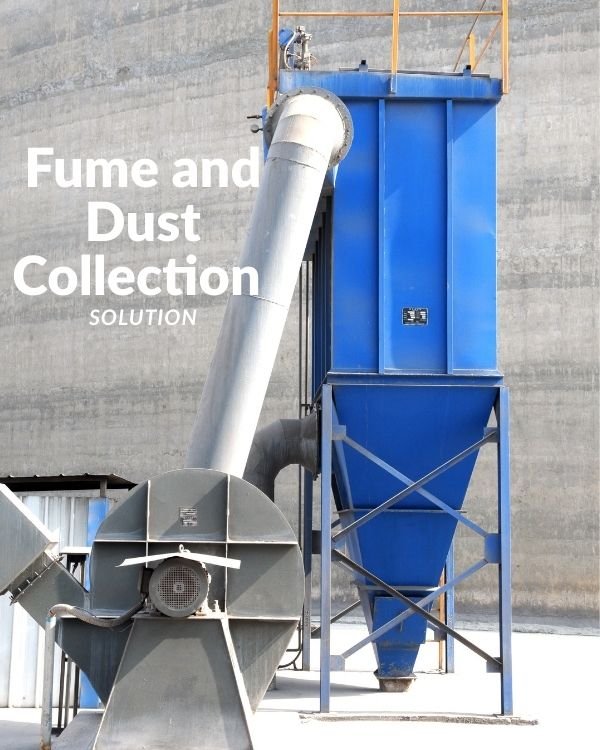

Fume and Dust Collection Systems

Fume and Dust Collection Systems for Industrial Furnaces

Our Air Box Pulse Bag Filters and Cyclone Dust Collectors are designed to remove dust efficiently and fumes from aluminum and zinc melting, casting, and other high-dust industrial processes.

With advanced pulse cleaning, strong dust removal capacity, and a compact, modular design, our systems ensure compliance with environmental standards while lowering operational costs.

Environmental Compliance – Meet strict emission regulations and pass inspections easily

High Filtration Efficiency – Capture both large and fine particles, reducing airborne hazards

Long Service Life – Durable filter bags with strong ash-cleaning capability

Low Maintenance – Easy bag replacement, minimal downtime, fewer moving parts

Customizable Design – Adapt voltage, size, and airflow to local regulations and plant needs

Need more options?

Didn’t find the exact dust collection solution you need?

We design and build custom fume and dust control systems to meet your plant’s air volume, dust type, and regulatory requirements.

Solving the Key Challenges in Aluminum Holding

Industry Challenges

Failing environmental inspections due to poor filtration efficiency

High operating costs of electrostatic precipitators (ESP)

Short filter cleaning intervals and frequent maintenance

Inflexible systems that don’t fit specific dust types or air volumes

Poor after-sales support from equipment suppliers

Our Solutions

High-Efficiency Pulse Bag Filters

Advanced chamber-structured pulse cleaning delivers consistent filtration performance to meet strict emission standards.

Energy-Efficient Alternatives

Large Pulse Valve Cleaning System

Strong pulse cleaning extends filter life and reduces maintenance frequency.

Fully Customizable Designs

Full Technical & Installation Support

Free technical consultation, design drawings, overseas installation team, and two-year warranty on key parts.

Why Choose us

Real Engineering. Real Performance. Real Results.

Every furnace is tailored to your voltage, layout, and production goals.

Designed to meet your target capacity—efficient, stable, and scalable.

Advanced design principles with locally supported manufacturing.

Fume treatment and energy-saving solutions to meet environmental standards.

Trusted partner for OEM/ODM clients with full confidentiality assurance.

Pre-sale consultation and 24/7 post-sale service.

Backed by 150+ invention patents and collaborations with leading universities, we continuously deliver cutting-edge, high-performance systems.

From furnace design to whole plant layout and environmental systems — we help you save cost, avoid safety risks, and ensure process integration.

From melting, holding, and crucible furnaces to fume treatment and aluminum transport systems — we cover all your aluminum and zinc alloy processing needs.

Join 3,000+ Industrial Clients Who Trust Yeasun

We don’t just build furnaces — we build long-term partnerships.

Join a global community of manufacturers who rely on Yeasun for energy-efficient, custom-engineered thermal systems.

Common Questions

Frequently Asked Questions

Find answers to the most common questions about our fume and dust collection systems — from filtration efficiency and maintenance schedules to customization and installation support.

Our pulse bag filters achieve ≥99% efficiency, and cyclone collectors ≥90%.

Yes, both voltage and motor specifications can be customized to meet local standards.

Typically every 2–3 years, depending on dust type and operating conditions.

Yes, the chamber design allows maintenance without stopping the entire system.

Yes, we offer on-site installation or remote video guidance, plus two-year warranty for key parts.