Turnkey Plant Solutions

From concept to commissioning — complete plant planning, equipment integration, and seamless delivery for safe, efficient, and cost-effective operations.

End-to-End Turnkey Foundry Solutions for Aluminum & Zinc Casting

Our Turnkey Plant Solutions provide end-to-end support for aluminum and zinc casting facilities — covering every stage from initial planning to final commissioning.

We help customers optimize plant layout, select and integrate equipment, and ensure safety compliance, avoiding costly rework and operational risks caused by

Cost Savings – Avoid unnecessary investments and operational inefficiencies

Safety Assurance – Comprehensive planning prevents layout and equipment hazards

Single-Source Responsibility – One partner for design, equipment, installation, and support

Faster Time-to-Production – Coordinated delivery and commissioning reduce project delays

Custom-Tailored Designs – Adapted to your production capacity, metal type, and facility space

Need more options?

Looking for a fully customized plant solution?

We can design, supply, and install a complete foundry tailored to your space, capacity, and production goals.

Solving the Biggest Challenges in Plant Setup

Industry Challenges

Incomplete plant planning leading to inefficiencies or hazards

Incomplete plant planning leading to inefficiencies or hazards

Multiple suppliers complicating project management

Delays in commissioning and startup

Lack of in-house technical expertise

Our Solutions

Comprehensive Layout Design

We consider every operational detail, from furnace placement to transfer routes, ensuring efficiency and safety.

Optimized Equipment Matching

One-Stop Turnkey Execution

We handle everything — design, manufacturing, installation, and commissioning — under one contract.

Coordinated Project Scheduling

Expert Engineering Support

Our experienced engineers provide guidance throughout the project, ensuring technical compliance and performance.

Why Choose us

Real People. Real Work. Real Rewards.

Bibendum placerat massa enim eget diam conubia ac metus posuere tempor letius.

Bibendum placerat massa enim eget diam conubia ac metus posuere tempor letius.

Bibendum placerat massa enim eget diam conubia ac metus posuere tempor letius.

Bibendum placerat massa enim eget diam conubia ac metus posuere tempor letius.

Bibendum placerat massa enim eget diam conubia ac metus posuere tempor letius.

Bibendum placerat massa enim eget diam conubia ac metus posuere tempor letius.

Bibendum placerat massa enim eget diam conubia ac metus posuere tempor letius.

Bibendum placerat massa enim eget diam conubia ac metus posuere tempor letius.

Bibendum placerat massa enim eget diam conubia ac metus posuere tempor letius.

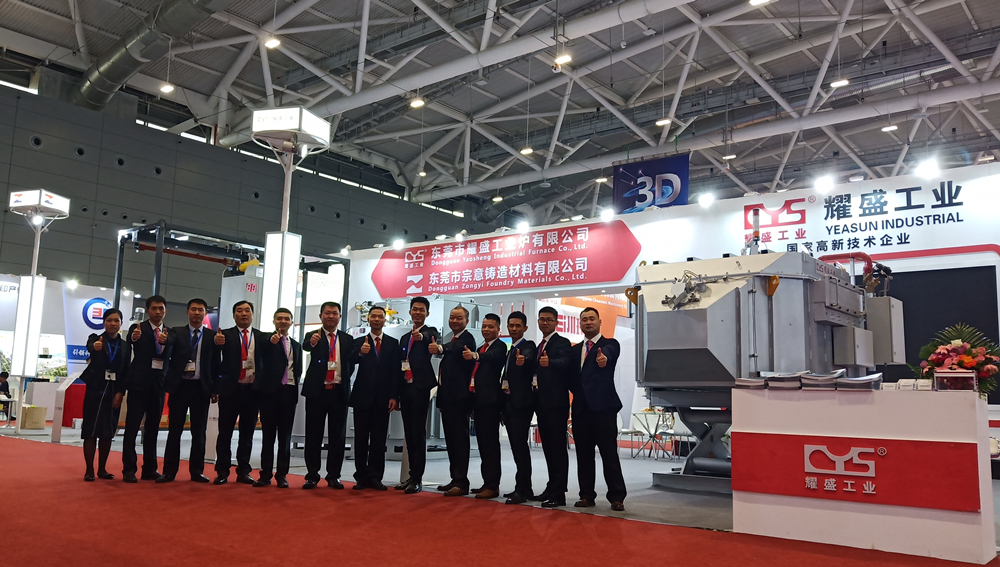

Join 3,000+ Industrial Clients Who Trust Yeasun

We don’t just build furnaces — we build long-term partnerships.

Join a global community of manufacturers who rely on Yeasun for energy-efficient, custom-engineered thermal systems.

Common Questions

Everything You Need to Know

We’ve gathered the key questions our clients ask about turnkey plant projects, so you can quickly understand our process, capabilities, and how we can deliver a complete solution for your foundry.

Yes, we can integrate new and existing equipment into a cohesive layout.

Depending on scale, typically 3–9 months from design approval to commissioning.

Yes, we provide full turnkey services worldwide.

Plant layout, equipment supply, installation, commissioning, training, and after-sales support.

Yes, we can plan layouts that allow easy capacity upgrades.